Submarine Rescue System

Teddington designed the In-Line Pressure Balanced Double-Gimbal Expansion Joint Assembly for the latest Submarine Rescue System.

One of Teddington’s proudest innovations is in that of the submarine rescue system.

The UK was entirely dependent on the US for submarine rescue until 1988 when the LR5 became the UK’s first dedicated rescue submersible. Originally the LR5 was a diver lock-out submersible to work in the oil sector, mainly the North Sea. In the 1990s, Teddington was approached to assist with the re-design of LR5 implementing the design and manufacture of a bellows expansion joint that would be used as an integral part of the submarine rescue system for most of the submarine fleets in NATO navies.

The aft propulsion module and the diver lockout chamber were replaced with a single new rescue chamber compartment in order to convert LR5 into a submarine rescue system. This required the addition of a larger diameter hemispherical section under the lockout hatch to mate with the rescue hatch, which is now fitted to the majority of the world’s naval submarines.

However, as a rescue submersible, LR5 had two main shortcomings: firstly, it could only really rescue five people at a time and if they had been under a limited range of pressure; secondly, they could not be transferred easily to a decompression chamber. In the 1990s, a study was conducted by one of the world’s leading offshore engineering and defence companies to look at the feasibility of increasing the rescue compartment capacity and adding a Transfer Under Pressure (TUP) facility, now standard on all submarine rescue vehicles.

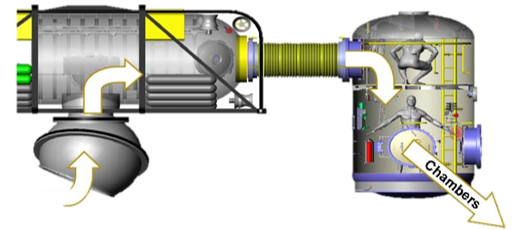

The final conversion in 1999 took LR5 out of service for just 6 weeks after which it was re-commissioned as a fully TUP-capable rescue submersible, implementing the Teddington designed In-Line Pressure Balanced Double-Gimbal Expansion Joint Assembly. This has proved very effective and has become the baseline design pattern for all submarine rescue vehicles from that point on.

LR5 proved very successful as a surface-ship launched rapid-reaction, flexible rescue vehicle and the addition of a portable ‘A’ frame meant the system could be air transported and deployed from a ‘ship of opportunity’. Until 2008, LR5 formed the basis of the Submarine Rescue Service until the arrival of the new NSRS.

After the sinking of the Kursk in 2000, Teddington was again approached due to our experience on the LR5 submarine rescue system, this time under the direct instruction of European NATO members and working alongside the leading companies in submersible and deep-sea applications. Forming a critical part of NSRS, the Teddington designed Flexible Manway Expansion Joint Assembly, has been in service since 2008. The system, fully air portable with its own TUP facility and decompression chambers provides global rescue cover within 48 hours.

Further projects have since been undertaken for navies in four continents, all built to the same fundamental Teddington design.

The US replacement for the DSRVs – the Submarine Rescue Diving and Recompression System (SRDRS), though larger and in higher grade materials, also adopted the Teddington designed Expansion Joint Assembly and the stern transfer lock, although the actual submersible is a single compartment, tethered vehicle.

So far, whether in drills, training exercises or real-life emergencies, Teddington’s product and the system generally has operated with a 100% effectiveness.

.png)