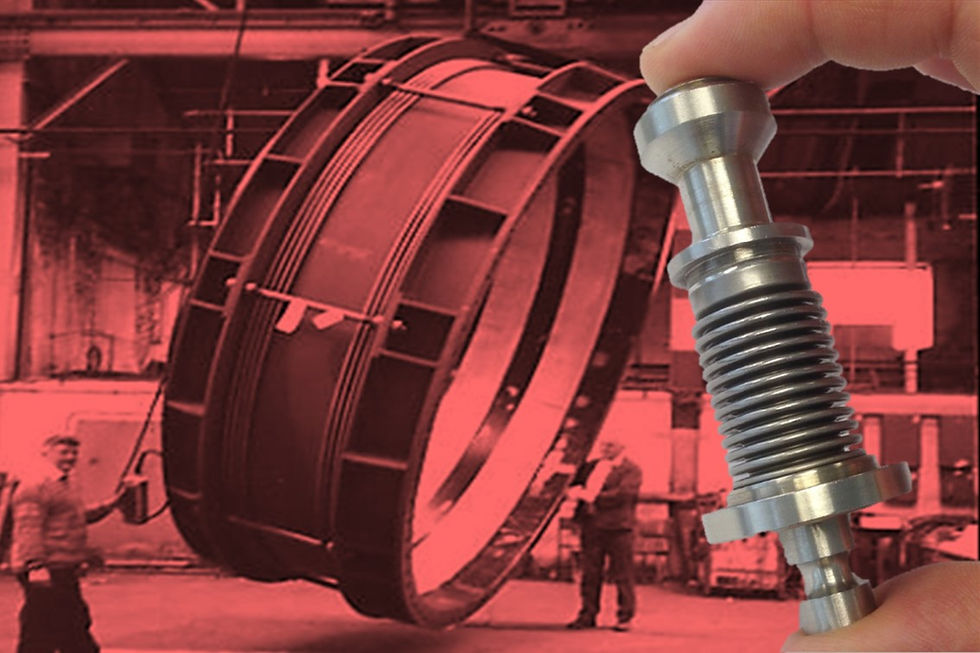

Any Environment Bellows

%20Any%20Environment%20Bellows.jpg)

Designed to perform in any environment, our metal bellows expansion joints withstand extreme heat, vacuum, pressure, vibrations, chemicals and mechanical stress, customised for superior flexibility, longevity, capability, reliability and system protection. Built from the highest-grade alloys, and synthetic materials, they will last in demanding industries such as power generation, chemical processing, marine systems and more, with no need to discard well into the future.

What 'Any Environment Bellows' Means

'Any Environment Bellows' focuses on the external operating environment - not the media inside the line (covered on Any Media Bellows) and not the size range (covered on Any Size Bellows).

We engineer bellows to cope with environmental factors such as:

-

High temperature and radiant heat zones;

-

Cryogenic temperatures and thermal cycling;

-

Outdoor weathering (UV, salt-laden air, rain);

-

Corrosive atmospheres (marine/offshore exposure, industrial fumes);

-

High-pressure external conditions;

-

Vacuum service and low-pressure external conditions;

-

Vibration and pulsation in machinery-connected pipework;

-

Restricted access and maintenance constraints (retrofit environments).

Environmental conditions influence bellows material, wall thickness, ply design, protection, hardware selection and documentation/testing requirements.

Environments We Design Bellows For

High temperature bellows

Bellows for high temperature duty are common in:

-

Steam lines, high-temperature process pipework

-

Exhaust systems, turbine and engine exhaust bellows

-

Flues and ducting (often paired with fabric expansion joints)

Key considerations:

-

Material selection for temperature and oxidation resistance

-

Fatigue life under thermal cycling

-

Thermal growth, anchor loads and guidance

Cryogenic bellows

Cryogenic bellows are used where:

-

Temperatures are extremely low and thermal contraction is significant

-

System flexibility is essential to protect equipment connections

Key considerations:

-

Material suitability at low temperature

-

Avoiding brittle behaviour and managing thermal shock

-

Leakage performance and testing approach

High pressure bellows (deep-sea and offshore duty)

High pressure bellows are used where internal or external pressures are extreme, including:

-

Deep-sea and subsea systems, where hydrostatic pressure increases with depth

-

Offshore oil and gas installations, including drilling and production equipment

-

Submarine and naval applications, where pressure integrity is critical

Key considerations:

-

Buckling and collapse resistance under high pressure

-

Wall thickness and bellows geometry to maintain stability

-

Fatigue life under combined pressure and movement

-

Material selection for strength and corrosion resistance

Vacuum and low-pressure external environments

Where vacuum integrity or leak-tightness is critical, design and verification must reflect the duty.

Key considerations:

-

Bellows geometry and stability

-

Leak testing approach (e.g., helium leak testing where specified)

-

Suitability of joints and end connections for vacuum service

Corrosive atmosphere bellows (marine/offshore/industrial)

Even when internal media is benign, the outside atmosphere can be highly aggressive.

Key considerations:

-

Corrosion-resistant alloys and suitable coatings

-

Protective shrouds and external hardware selection

-

Inspection and documentation to project requirements

Outdoor and weather-exposed bellows

Outdoor environments can introduce:

-

UV exposure, rain ingress, freeze-thaw cycles

-

Salt spray (coastal/marine installations)

-

Contamination from dust and particulates

Key considerations:

-

Protective covers and coatings

-

Hardware materials and corrosion resistance

-

Drainage, access and maintainability

Bellows Types Selected By Environment

We select the bellows type based on environmental duty:

Are much more versatile than other materials Can be made of many different grades of stainless steel or nickel alloy Can be suitable for high-or-low-temperature, pressure-cycling or fatigue-critical environments. Are used in every possible sector or application type, including but not limited to power, LNG, marine, industry and so much more.

Are most commonly used for hot gas handling. Are most suitable for large ducting systems. Are capable of absorbing extreme movement, vibration and noise. Can be very lightweight.

Are capable of absorbing extreme movement, vibration and noise. Can be suitable for many outdoor pump and pipework environments. Are most commonly used for water media.

Are ideal for when chemical resistance is a priority. Are common in plants where external chemical exposure or washdown regimes are present.

Design features that improve reliability in harsh environments

To maximise bellows life and reduce premature failures, we consider:

-

Covers and shrouds to protect convolutions from damage and contamination

-

Internal liners (where needed) to protect bellows from flow-induced turbulence and vibration;

-

Coatings and surface preparation for corrosion protection (where specified);

-

Hardware selection (tie rods, hinges, frames) to resist environmental degradation;

-

Design support on anchors, guides and alignment to prevent overload and mis-installation;

-

Documentation packages aligned to project standards and inspections.

|  |

|---|---|

|  |

Environmetally-Focused Specifications We Need From You

To specify the environmental conditions for your bellows, please provide:

-

Environment description (indoor/outdoor, marine/coastal, chemical plant, washdown, dust);

-

Ambient temperature range and proximity to radiant heat sources;

-

Any expected thermal cycling or rapid temperature changes;

-

Vibration and pulsation conditions (if connected to rotating equipment);

-

Operating pressure, temperature and required movements (axial/lateral/angular);

-

Required service life-cycles and any inspection or testing requirements;

-

Access constraints (maintenance, installation limitations, retrofit requirements).

Send a drawing or spec and we’ll recommend a bellows solution with the right material and protection for the environment.

FAQS About 'Any Environment Bellows'

What’s the difference between “Any Environment” and “Any Media” bellows? “Any Environment” focuses on external conditions around the bellows (heat, weather, vacuum, corrosion). “Any Media” focuses on what flows inside the system.

Can you supply high temperature bellows for exhaust systems? Yes. We supply high temperature metal bellows for exhaust and hot gas duties, designed for vibration and thermal cycling.

Do you design bellows for outdoor or marine exposure? Yes. We can specify corrosion-resistant materials, coatings and protective features for coastal, marine and offshore environments.

Are bellows suitable for cryogenic applications? Yes. Cryogenic bellows can be engineered for low-temperature service; material selection and testing approach are critical.

Can you help prevent premature bellows failures? Yes. Many failures come from misalignment, insufficient guides/anchors or unaccounted environmental factors. We can advise on layout and installation requirements.

Read more FAQs here

.png)