History

Since 1927, we have been manufacturing bellows expansion joints from brass and copper to nickel and titanium. We have been at the cutting edge of our industry, from the first UK patent for bellows to submarine rescue systems in which people are the bellow’s media.

British Thermostat Company

Teddington Engineered Solutions started in 1927 as the British Thermostat Company in Teddington, based besides the Thames just outside London. The company issued the first British patent for bellows in 1928, and began designing and manufacturing brass and copper bellows for the design and manufacturing of the automatic thermostats used to this day in heating and cooling apparatus. Initially they were used in domestic products like fridges and ovens, and later control instruments for aircraft. By 1933, the company had grown so much it relocated to a larger site in Sunbury-on-Thames, London.

As World War II began, the British Thermostat Company forged a close working relationship with the military. The company designed and manufactured aircraft controls and instrumentation for various purposes including altitude measurement and air supply systems. However, we remain most proud of our contribution to the exhaust systems used in the groundbreaking Merlin Engine powering the legendary Supermarine Spitfire, Hawker Hurricane and Lancaster Bomber, that helped Britain win the Battle of Britain and achieve air superiority over Europe. Later in the war, the company began supplying parts for naval applications in the upgrading of warships and submarines. Production was so high, a railway was even built leading to the factory for the supply of torpedo heads for submarines, supplying both British and American boats.

%20WWII%20Ship_edited.jpg)

%20WWII%20Submarine.jpg)

%20WWII%20Spitfire_edited.jpg)

Teddington Aircraft Controls

After the war, the British Thermostat Company would diverge, rebrand and relocate: Half of the company remained in Sunbury-upon-Thames and rebranded as Teddington Controls in 1954, continuing with domestic appliance products and other heating/cooling systems. What would later become Teddington Bellows relocated to Merthyr (Wales) in 1946 and rebranded as Teddington Aircraft Controls in 1956, continuing with aircraft instrumentation, designing and manufacturing stainless steel bellows for aircraft and other industries.

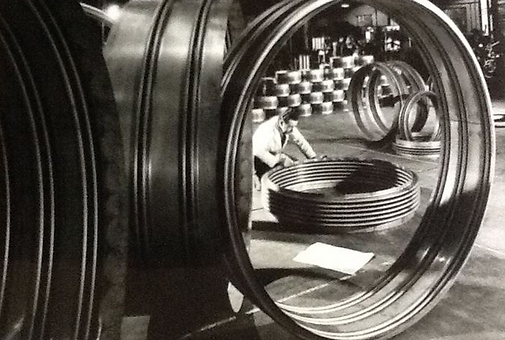

In 1960, Teddington Aircraft Controls relocated from Merthyr to Pontardulais where Teddington continued designing and manufacturing bellows for aircraft and other industries. For example, that same year, Teddington engineered the pressure switch bellows assembly for the De Havilland Comet, the world’s first commercial jet airliner, which revolutionised international travel for the average person. And throughout the decade, Teddington engineered and manufactured the expansion joints for Britain’s nine full-scale Magnox nuclear power plants, the first in Britain and the world.

%20Pontarddulais%20Factory%20Int.png)

%20Pontarddulais%20Factory%20Int.png)

%20Pontarddulais%20Factory%20Int.png)

Teddington Bellows

Teddington Aircraft Controls’ increasing specialisation in bellows led to expansion into more industrial sectors and rebranding to Teddington Bellows in 1964. Teddington Bellows went on to design and manufacture for many prestigious projects, such as: cutting new-edge cryogenic expansion joints for the first cryogenic LNG tanker-ships in 1968; the complete tuyere stocks for high-temperature and high-pressure conditions in blast furnaces from 1970, incorporating upper and lower downlegs; bellows assemblies for use on environment control systems of the NatWest Tower in 1979, London’s first skyscraper; bellows assemblies for the Sellinge 420 kV sub-station for the Cross Channel Link in 1990; and continuing configurations for military applications, from nuclear submarines and surface warships to Tornado fighter-bombers, Harrier jump-jets and Merlin helicopters.

A recent notable innovation is in our contribution to a revolutionary submarine rescue system. Prior to the advent of the LR5 SRV (Submarine Rescue Vehicle), there was little that could be done for crewmembers in a distressed submarine, but the LR5 can dock with a sunken submarine and bring crewmembers to a rescue ship on the surface. Teddington designed and manufactured the in-line pressure balanced double-gimbal bellows assembly in the transfer-under-pressure system from the LR5 to a decompression chamber on the deck of the ship for rescued crewmembers. As well as saving lives, we believe it may be the best example of a bellows assembly in which the media is neither gas nor liquid, but people! In later years, Teddington has designed similar assemblies for various navies and defence organisation across the world.

%20De%20Havilland%20Comet.jpg)

%20Calder%20Hall.jpg)

%20Tuyere%20Stocks.jpg)

%20Tower%2042.jpg)

%20Tornado%20Jet.jpg)

%20Methane%20Pioneer.jpg)

%20NSRS.jpg)

Teddington Engineered Solutions

In 1999, Teddington Bellows merged with Vokes-Genflex (estd. 1931) and in 2000 with Brockington & Scott (estd. 1959), two well-established bellows expansion joints manufacturers, combining their assets, specialists and expertise. Soon after, in 2003, Teddington Bellows was purchased by MBO, and rebranded as Teddington Engineered Solutions, relocating to Llanelli in 2004. In 2007, Teddington Engineered Solutions expanded its operations to a second factory, purchasing and relocating one of its suppliers, to form Teddington Components from where it develops and manufactures various bellows and pipe fittings and components.

Teddington Engineered Solutions has a long and proud history, a rich portfolio with one of the best reputations of any expansion joints manufacturer on the market. We have been at the cutting edge of our industry at every step. With leading experience in every major industrial sector requiring bellows and expansion joints, no one has more experience and a better performance record in safety critical applications for almost a century. No challenge is insurmountable and no solution is unachievable. Teddington is your safest, easiest and most reliable option for your design and manufacturing needs – contact an engineer at no cost today.

.png)