Any Media Bellows

%20Any%20Media.png)

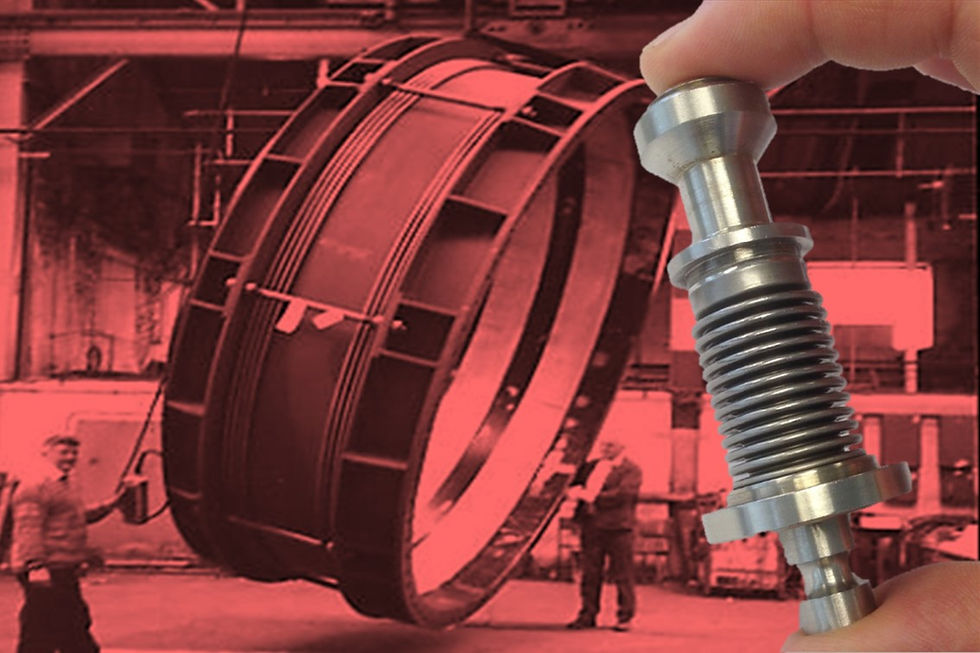

Our metal bellows expansion joints are engineered to handle any media, including gas, steam, water, saltwater, oil, aggressive chemicals and molten fluids. Built with corrosion-resistant alloys such as Inconel, Incoloy, Monel, Hastelloy, titanium or aluminium, these partly or non-ferrous bellows ensure reliable performance in demanding environments. Suitable for any applications, from chemical processing to metallurgy, HVAC to energy, they offer maximum durability and capability.

What 'Any Media Bellows' Means

What “Any Media Bellows” means

“Any Media Bellows” refers to our capability to design bellows that are compatible with the media they carry, including:

-

Steam and condensate

-

Hot exhaust gas and flue gas

-

Air and inert gases

-

Oil, fuel and hydrocarbons

-

Water, slurry and particulate-laden media

-

Aggressive chemicals and corrosive fluids

Media compatibility directly affects material choice, bellows construction, liner design, corrosion allowance and fatigue life. This page focuses on getting those decisions right.

Typical applications by media type

Water

-

Freshwater, saltwater, wastewater, HVAC and more

-

Rubber or metal bellows

Liquids & hydrocarbons

-

Oil, fuel and process liquids in industrial pipework

-

Metal or rubber bellows selected to manage pressure and vibration

Molten solids

-

Molten plastics

-

High-temperature-resistant metal bellows

Steam & condensate

-

Boiler connections, turbine pipework, condensate lines

-

High-temperature metal expansion bellows with fatigue-rated designs

Cryogenic fluids

-

Liquified natural gas (LNG) or liquefied petroleum gas (LGP)

-

Nickel alloy expansion joints

Powdered solids

-

Cement, lime and mineral powders

-

Corrosion-resistant metal bellows

Exhaust & flue gas

-

Engine exhaust bellows, turbine exhaust, ducting

-

Metal bellows or fabric bellows depending on pressure and temperature

Chemical & corrosive media

-

Acids, solvents and aggressive fluids

-

PTFE bellows or lined designs to protect metallic components

Live personnel

-

Human transfer-under-pressure systems such as submarine rescue

-

Pressurised metal expansion joints

Bellows Types Selected By Media

We select the ideal material depending on the media:

Steam, gas, exhaust, oil, chemicals, more Ideal for steam, exhaust gas, high-temperature air and hydrocarbon service Used in metal expansion joints for power, LNG, marine and industrial pipework

Water, mild chemicals Suitable for water, cooling systems, HVAC, and some mild chemical duties Excellent for noise and vibration reduction

Hot gas, low pressure Designed for flue gas, hot air and exhaust ducting Common in power generation, CHP and industrial ventilation systems

Aggressive chemicals Used for corrosive, high-purity or chemically aggressive media Suitable for chemical processing, pharmaceutical and specialist plants

Engineering Support & Validation

Customising the correct bellows for the correct media is not just about selecting the correct materials.

One must also consider:

-

Engineering review of media, duty cycle and failure modes

-

Finite Element Analysis (FEA) where fatigue or stress is critical

-

Advice on pipework layout, guides and anchors to prevent overload

-

Integration with testing and inspection requirements where specified

-

And many other contextual factors

Meticulously approaching these issues reduces risk of premature failures caused by corrosion, erosion or unexpected loading.

Media-Focused Specifications

Specifications we would require from you would include:

-

Process media (including composition, concentration and contaminants)

-

Operating and design temperature

-

Operating and design pressure

-

Required movement (axial, lateral, angular) and cycle life

-

Any cleanliness, purity or contamination requirements

-

Preferred bellows type if known (metal, rubber, fabric, PTFE)

-

Required standards, approvals or testing

Send a drawing, datasheet or basic description and our engineers will recommend a bellows solution compatible with your media.

FAQS About 'Any Environment Bellows'

How do you choose the right material for my media? We assess chemical compatibility, temperature, pressure and cycle requirements before selecting materials and bellows construction.

Can metal bellows be used with corrosive media? In some cases, yes, using appropriate alloys or liners. For aggressive chemicals, PTFE bellows are often more suitable.

Do you design bellows for dirty or abrasive media? Yes. For abrasive or particulate-laden media we consider liners, material thickness and geometry to minimise erosion.

Can one bellows handle multiple media? If operating conditions vary, we design to the worst-case media to ensure safe operation across all scenarios.

Read more FAQs here

.png)